exaCT L

The integrated desk on the exaCT M serves as a workspace for measurement and data analysis forming a perfectly designed, ergonomic workstation. Software, service, consultation and training are also integrated. This machine is top performing and the integrated application software is very user friendly.

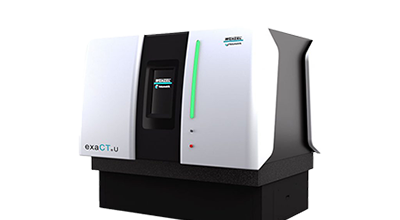

exaCT U

The exaCT U is the new generation of industrial computed tomography. This machine can be used universally and is designed in such a way that each customer can tailor his individual system with the appropriate X-ray source and detector. Precise measurements can also be generated after a short training period.

GT Series 450

The GT 450 gear measuring machine is typically used in the aerospace, automotive and their supplier industries. It allows the precise analysis of gears and rotationally symmetrical parts up to a diameter of 450 mm.

GT Series 650

Due to the maximum measurable diameter of 650 mm, the GT 650 is especially well suitable for the analysis of geared parts and shafts used in commercial vehicles, rail transmissions or construction and agricultural machinery.

SF 87

The new SF 87 Coordinate Measuring Machine is the universal measuring machine for the production environment. The SF 87 requires little floor space and is ideal for a large part of the metal cutting and forming industry.

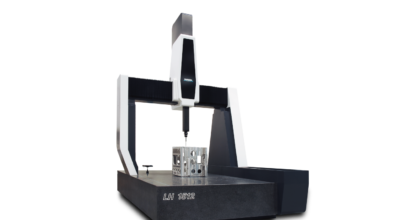

LH Large CMM

The Large LH CMM is the latest in high-performance Bridge style CMMs. The Large LH CMM combines the legacy of the LH CMM with a modern look, as well as the latest in sensor technology.

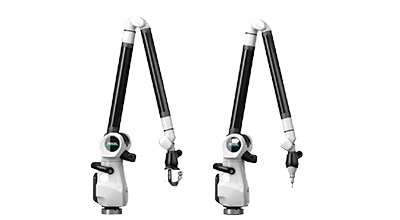

WM | MMA Series Mobile 7-Axis

By combining a portable 7-axis measuring arm with a high-resolution line scanner, which captures every detail contact-free, the measuring arms represent a useful complement to your established classical coordinate measuring systems.