WENZEL’s new shop floor CMMs

In recent years there has been increasing demand from WENZEL’s customers for machines that can be positioned on the shop floor as close to their production machines as possible. This push has primarily come from aerospace and medical companies that have a need to inspect 100% of their output and also to enable the fastest possible feedback to their manufacturing machines. In response to this demand WENZEL have produced 2 new CMMs, the Shop Floor SF 87 and SF 55.

The traditional home of the CMM in a company is in a clean lab environment with air conditioning, well away from the dirt, noise and vibration associated with metal forming processes and in the hands of QA professionals. The challenge for WENZEL has been to make machines that can be accurate and reliable in a far less ideal place, close to production and operated by less skilled personnel.

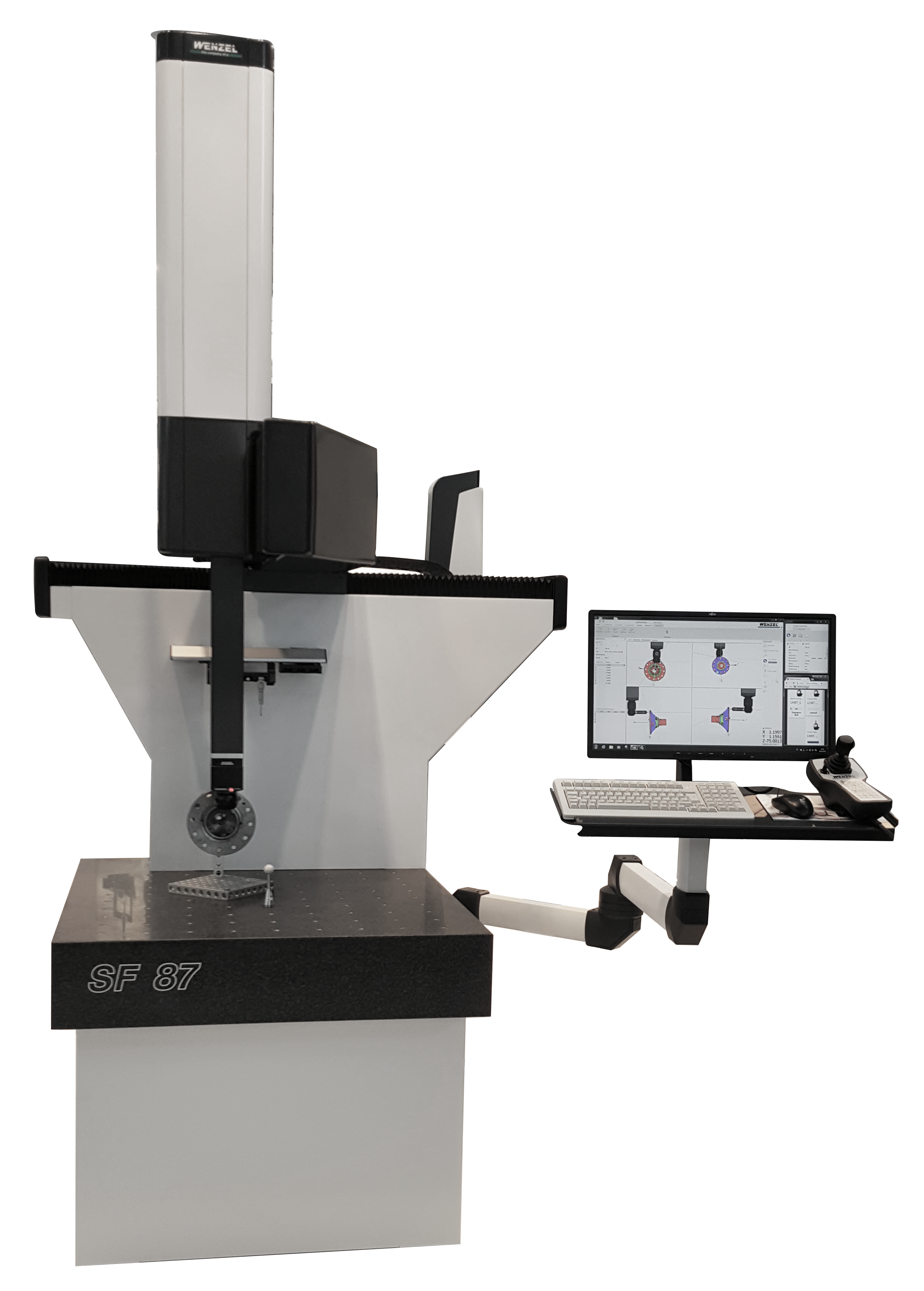

WENZEL SF 87

The new SF 87 coordinate measuring machine has been developed from the ground up as a measuring machine for the production environment. Notable features are the way that all the guide and drive mechanisms are mounted high up and out of the way of dirt and accidental spills. The mechanisms are also covered with sealed bellows that keep out airborne contaminants like dust and oil. To the same end, the optional tool changing rack is also high up and away from harm and the granite table is unobstructed, free of dirt traps and easily wiped off. The machine has passive damping as standard and can be fitted with active damping if needed. The SF 87 requires little floor space and offers an optimized measuring volume of 800 x 700 x 700 mm; This makes it ideal for a large part of the metal cutting and forming industry. The machine concept offers a very good price-performance ratio with low space requirements. High traversing speeds and accelerations ensure high productivity. The combination of powerful probes and optical sensors leads to a considerable increase in efficiency in the measuring and testing process.

WENZEL SF 55

Developed in conjunction with customers that had WENZEL CMMs that wanted to measure parts closer to production, the SF 55 is a CNC bridge measuring device for use on the shop floor that can be equipped with both tactile and optical sensors. The corrosion-free guides of the machine are made of granite and hand lapped with high precision then completely covered and protected against contamination by bellows. The controller and PC are integrated into the machine for a minimum footprint. The space requirement is low with an excellent price-performance ratio. The SF 55 has passive vibration damping as standard and can optionally be equipped with active vibration isolation.

Multi-sensor capability

Both the SF87 and SF55 are multi-sensor capable and ready for automation. Both of these shop floor CMMs are flexible when it comes to sensors. they are multi-sensor capable and support both optical and Renishaw tactile sensors including the sensational 5 AXIS REVO and PH20 probe systems, the SP25M analogue scanning probes as well as the full range of Wenzel Laser scanners. The SF machines can be configured with a tool-change rack to switch probes and extensions automatically, without need for time consuming re-qualification.

Integration

The new coordinate measuring machines are directly usable in a production line and easily integrated into automation solutions through the optional WENZEL Automation Interface (WAI) for material handling They use standard 120V or 240V power.

WENZEL complements its strong product range with service packages which includes all services such as software support, preventive maintenance, calibrations and repairs with genuine factory components.